A new electron and laser beam platform for industry accessibility

For industrial researchers assessing electron- and laser- beam technologies, or new materials or material powders to use with these technologies, this platform will provide equipment and user support for in operando experiments at the Swedish Materials Science beamline

New product and manufacturing possibilities

Electron- and laser- beam manufacturing/welding operations are becoming commonly used in industry. Industry sees opportunities to expand electron- and laser-beam operations to an ever-widening range of manufacturing activities and new product designs. New types of product designs and manufacturing processes are also possible due to the new materials and powder materials that have been specifically designed for use in beam cutting/welding manufacturing processes.

The challenge is that product quality is co-dependent on factors such as beam energy, production time and material choice. The relative newness of beam welding however limits the scope for experienced-based optimisation. Optimising product design and manufacturing processes therefore often requires a combination of modelling and experimental research to provide validated data for modelling. Research therefore requires access to electron/laser research equipment.

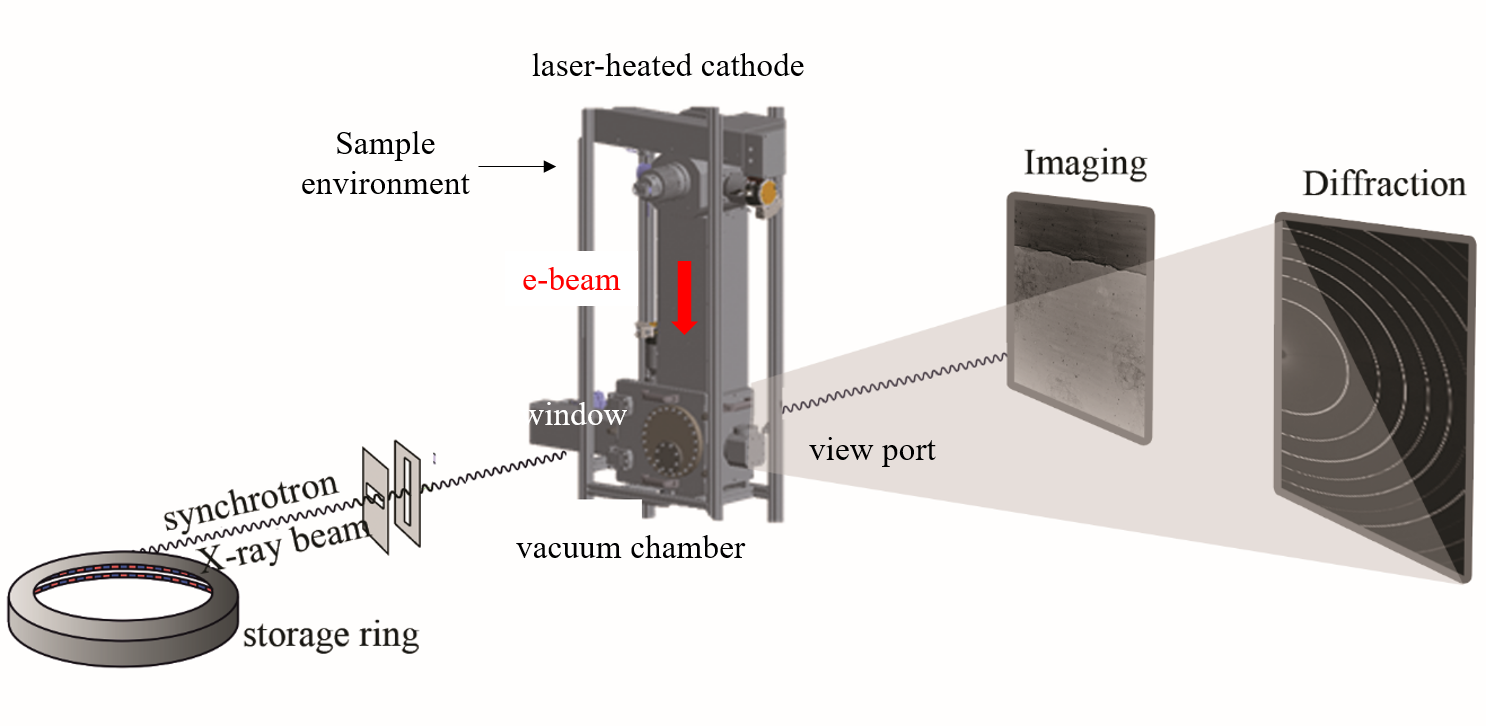

Several laboratories already provide access to equipment. However, sometimes it is necessary to also capture information during the welding operations in order to assess the underlying factors that determine product qualities. Factors such as melt pool dynamics, solidification, defect formation and solid-state phase transformations.

Access to such equipment in synchrotrons is therefore becoming increasingly important to increase the use of these technologies. However, designing such equipment for use in synchrotrons is a highly specialist task. It is therefore not realistic that researchers who design equipment or manufacturing processes will take the step from laboratories to synchrotrons on their own.

This project will therefore replicate laboratory electron- and laser- beam experimental equipment at the Swedish Materials Science beamline. Our ambition is to do that in a way that enables industry researchers to seamlessly move from laboratory experiments to in-operando experiments.

Project concept

This project will:

- Procure a platform of experimental equipment at the PETRA III Swedish Materials Science beamline so that industry researchers can capture experimental information about what is happening in-operando i.e. during the cutting/welding operations.

- Devise streamlined processes for using the equipment at the Swedish beamline, including how to prepare for beamline experiments in home laboratories as well as data analysis procedures

- Shape user support material and provide training so that industry researchers can start to use the platform in a straightforward way.

Project timeline for the laser equipment

We will procure a new laser and related equipment for the platform. The activities and timeline are:

2023

- Identification of lasers, components and their tentative specifications

- Briefing to the Swedish community to get feedback and input about the proposed specifications (June 2023)

- Specification update as input to the Procurement Process

2024

- Procurement process

- Installation

- Commission testing

2025 -

- Development of user manuals, training

- Support of industry users

Project timeline for the electron beam equipment

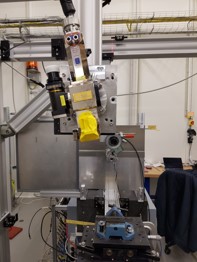

The electron beam equipment was designed and constructed in a project funded by the Röntgen-Ångström Cluster (RÅC), which has been ongoing from 2000 and will end in 2023. That project designed a mini electron beam additive manufacturing machine, which is described in this poster (pdf 6.5 MB) , and can be operated at synchrotrons to capture both imaging and diffraction data.

In this accessibility project, the activities and timeline to extend the use of the equipment to industry researcher is:

2023

- Assessment of the use-ability of the electron beam equipment for research use beyond the RÅC project

- Possible redesign and upgrade of the equipment

- Consideration of Health & Safety procedures for the operation of the equipment at the Swedish beamline

2024

- Briefing to the Swedish community about the equipment

- Development of user manuals, training etc

2024 - 2025

- Support of industry users

Project partners

The project participants are:

- Professor Peter Hedström (KTH), principal investigator

- Associate Professor Jörg Volpp (HV), who is technical lead on the laser-beam equipment, and Johanne Mouzon (LTU)

- Associate Professor Greta Lindwall (KTH), who is responsible for the electron-beam equipment

- Dr Denise McCluskey (KTH), who will coordinate training instances and disseminate information

- Dr William Hearn (KTH), who will shape methods

This project is financed by the Swedish Research Council (VR), grant number 2022-06078, as part of VR's programme to make synchrotron/neutron research infrastructures more accessible to, and more used by, the business and public sectors.

Contact

For further information about this project, or to provide input about your needs, please contact: