Community review of the Roll-in Station

On 21 June, 20 researchers and DESY staff joined the CeXS briefing about the proposed design and range of equipment options for the Roll-in Station. Feedback was positive. In the discussion of priorities, there was useful new input e.g. about the importance of rotation possibilities for stress/strain measurements. Feedback is open until end August.

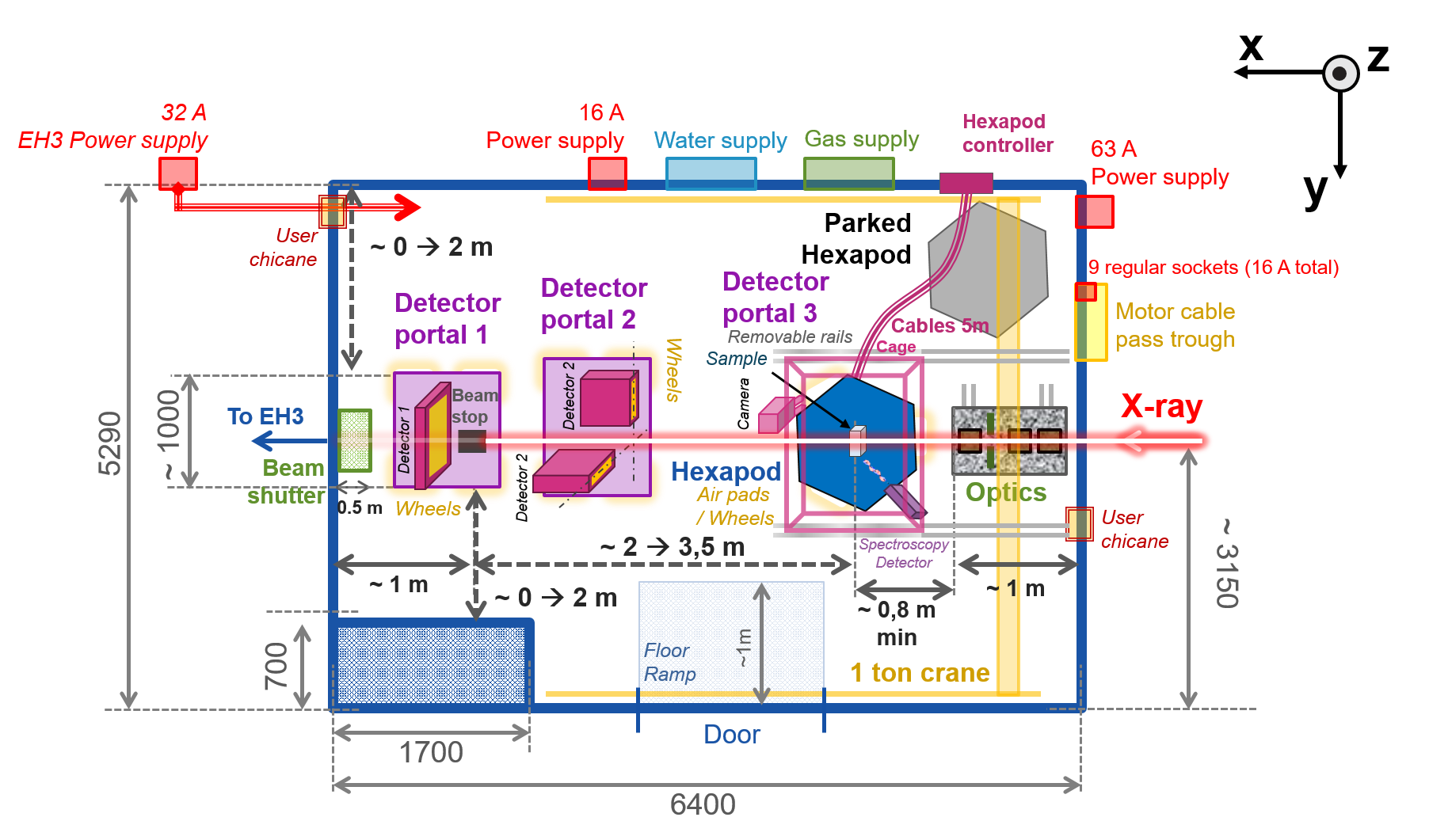

On 21 June, Gabriel Spartacus from CeXS presented the proposed design and range of equipment possibilities for the Roll-in Station, which will be located at the PETRA III Swedish Materials Science beamline's Experimental Hutch 2.

Complementarity to the instrumentation and sample environment support options already in place at the Swedish Materials Science beamline is the key design concern. In comparison to EH3, illustrated in the Table below, the novelty in the proposed Roll-in Station is::

- Support of large, bulky sample environments up to 1.5 tonnes

- Fast frame rates for data acquisition e.g. 4.5 k Hz or more

These features will be achieved via i) a hexapod mounted on airpads that will support a maximum payload of 1.5 tonnes as well as ii) two Detector Portals to enable flexibility in data acquisition modes. A large q-range will be enabled e.g. via VAREX detector, with fast acquisitions & imaging enabled via e.g. via 1 or 2 EIGER cameras. Additional options are SDD & CdTe spectrometers (low & high energy ranges).

There was a discussion of options such as a 3D-Digital image correlation camera and Welding camera aas well as equipment that would be useful complements to sample environments such as a Pump station and pyrometers. The possibility of a Rotation platform for the Hexapod was also discussed. The priorities of such options were discussed.

In the discussion, it became clear that the rotation platform option had primarily been considered from the perspective of precise alignment of the sample environment. However, a useful point was raised that rotating large sample environments could be especially when making stress/strain measurements - although submicron positioning may not be crucial in such cases.

Such points, the general views of priorities and the postive overall feedback will be taken into consideration during the work to refine the design and priorities for the tendering process.

The design work is ongoing, and input/feedback is welcome before 1 September. Please contact Gabriel Spartacus (spartac@kth.se).

Table 1. Complementarity of the proposed design with the existing capabilities of Experimental Hutch 3.

|

Experimental Hutch 2 (proposed) |

Experimental Hutch 3 |

|

Sample environment Weight < 1 500 kg (1 500 kg hexapod, noting the existing crane has a max |

Weight < ~ 400 kg (400 kg hexapod) |

|

Size < 3 x 3 x 2,5 m (l x w x h) |

Size < 1 x 1 x 2,5 m (l x w x h) |

|

WAXS, Imaging (radiography), Fluorescence |

SAXS, WAXS, Simultaneous SAXS/WAXS, |

|

Frame rate up to 4,5 kHz or more (detector ROI) |

Frame rate up to 1,2 kHz (EIGER pool detector) |

|

Focused beam size (FWHM):

Parallel beam size (FWHM):

|

Focused beam size (FWHM):

Parallel beam size (FWHM):

|