Fast current induced heating devices for ribbon / bulk materials

This device has been used to perform an in-situ XRD study of Cu-Zr-Al metallic glasses in order to map the phase evolution with respect to temperature.

Temperature induced phase evolution in metallic glasses

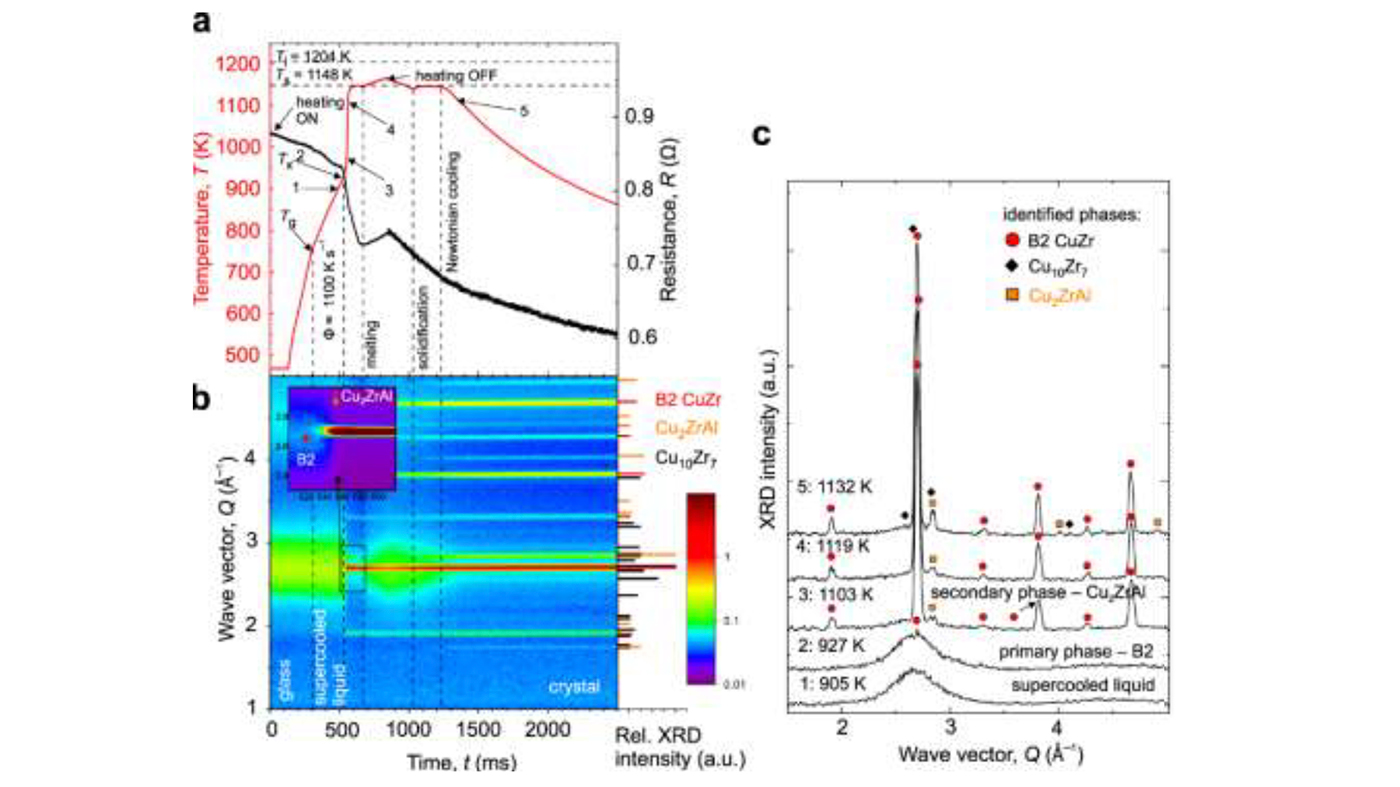

Orava et al. performed an in-situ XRD study of Cu-Zr-Al metallic glasses in order to map the phase evolution with respect to temperature. Ribbon samples were used and followed a flash-annealing up to a temperature of ~ 1200 K where the heating rate was ~1100 K/s. The chamber was either under vacuum or flushed with He (allowing a faster cooling). Identification of the crystalline phases which form upon cooling was possible, including the dependence of cooling rate. This study also used an electromagnetic levitation device for in-situ XRD, described in ref. [10].

Experiments were performed at the Swedish Materials Science beamline, P21.1 branch.

Read more about this research in R. Hermann, W. Löser, H.G. Lindenkreuz, W. Yang-Bitterlich, C. Mickel, A. Diefenbach, S. Schneider, W. Dreier, Metastable phase formation in undercooled Fe-Co melts under terrestrial and parabolic flight conditions, Microgravity Sci. Technol. 19 (2007) 5–10. doi.org/10.1007/BF02870982 .

Sample environment description

For a desciption of the sample enviornment and its specfications see: J. Orava et al. (2020) Rev. Sci. Instrum. Vol.91, No.073901

doi.org/10.1063/5.0005732