Cutting tool X-cut

This sample environment has been used for measuring the stress and temperature at and below the cutting edge of a TiAlNbN coated WC-Co tool - while the tool was cutting carbon steel.

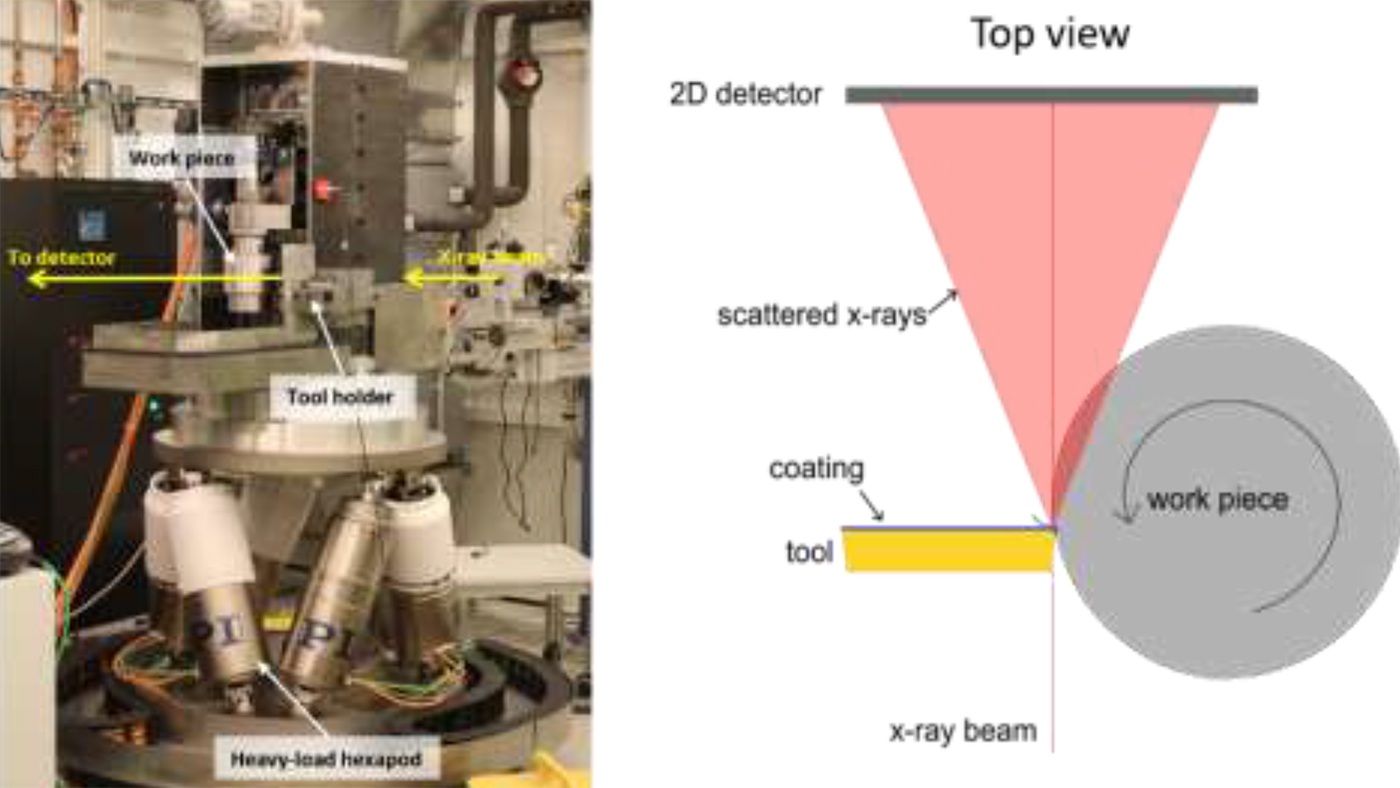

Sample environment

This sample environment replicates manufacturing using a tungsten carbite tool to cut metal. It has been designed to keep the tool/metal interface within the x-ray beam to enable real time measurements throughout a complete cutting process cycle. The article below by Rogström et al. describes this sample environment and provides a demonstration of its research capabilities.

Study of performance of tools and their surface coatings

This work aimed at measuring the stress and temperature at the cutting edge of a TiAlNbN coated WC-Co cutting tool during cutting of carbon steel. The workpiece rotation speed was set to 800 rpm and the feed rate of the cutting was set to the maximum of 0.3 mm/revolution. In operando XRD where performed during cutting and enabled determination of in-plane stresses and temperatures through the variation of the lattice parameters of the phases present in the cutting tool.

These particular experiments were performed at the P07 beamline at PETRA III. This sample environment has also been used at the PETRA III Swedish Materials Science beamline.

For futher information see L. Rogström et al. (2019) Review of Scientific Instruments, Vol.90, No. 103901 doi.org/10.1063/1.5091766