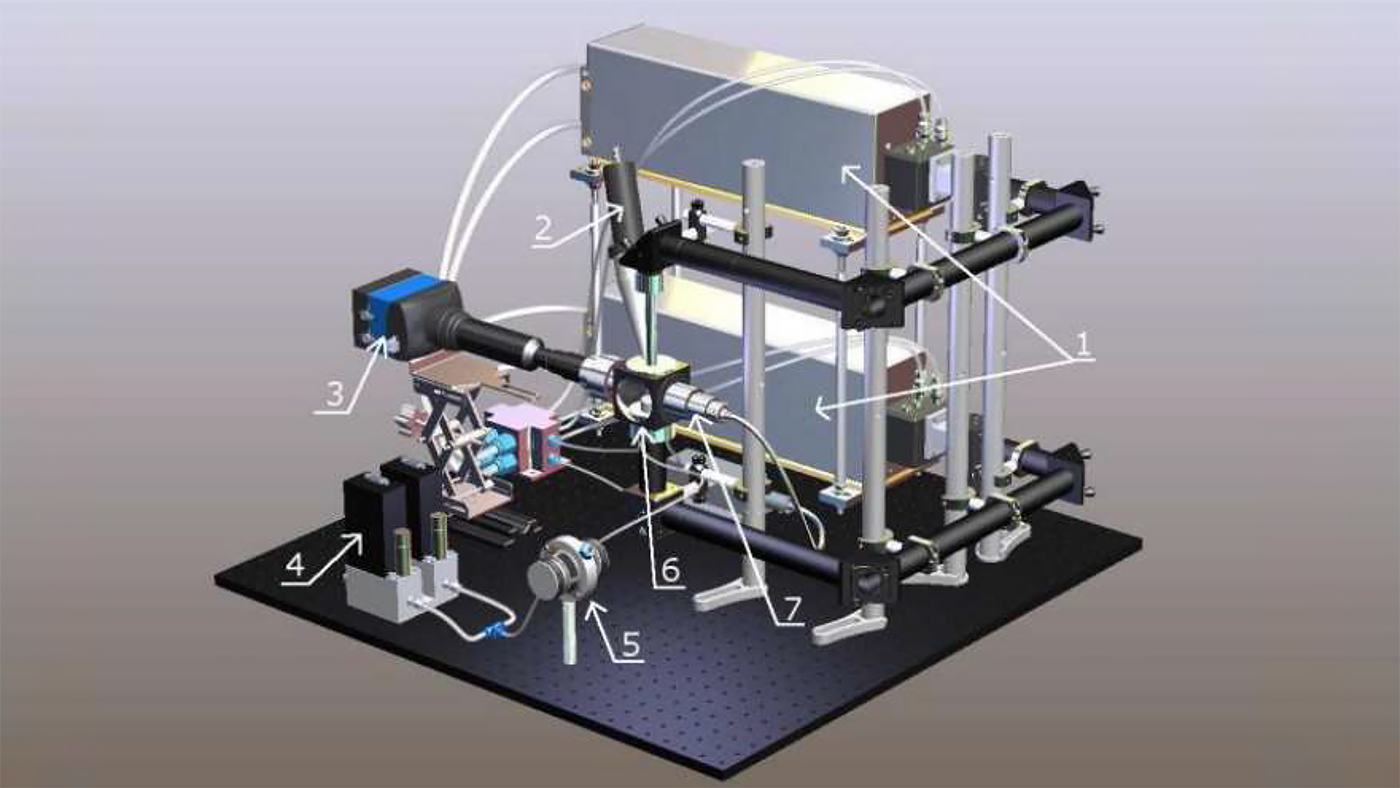

Aerodynamic Levitation (ADL) system

This levitation setup with lasers, pyrometer, high-speed camera, mass-flow controller, acoustic excitation system and levitation chamber enables studies of the solidification of 2mm diameter melt samples - during the cooling process - at cooling rates ranging between 300 K/s and 1 K/s.

Levitation sample environment

A levitation setup with lasers, pyrometer, high-speed camera, mass-flow controller, acoustic excitation system and levitation chamber enables studies of the solidification of melt samples - during the cooling process - at cooling rates ranging between 300 K/s and 1 K/s.

- Typical sample size: 2 mm in diameter

- Thermophysical property measurements (density, surface tension, viscosity) and in-situ measurements of solidification phase formation and evolution of materials (primarily oxides) at temperatures (500K-2500K material dependent).

- Heating is performed by two 30 W SynRAD Firestar v40 CO2-lasers

- Spot size of the laser at the sample position is about 1 mm in diameter

- Temperature measurements are carried out using a single-color pyrometer (which should be calibrated to the material’s emissivity). Different pyrometers are available.

- Various gas-atmospheres can be selected (Ar, Ar+O2).

- High-speed camera imaging of droplets from the side with telecentric optics (~2.6µm/pixel resolution)

For a fuller description of the sample environment see F. Kargl et al. (2015) Int. J. Microgravity Sci. Appl. Vol.32 No.2, p.320212. doi.org/10.15011/ijmsa.32.320212

Research example

Schraut et al. studied the solidification of the CaO–SiO2 system, with different CaO amounts (between 70 and 80 mol%). They used the ADL device in order to melt the samples and observed their solidification upon cooling at cooling rates ranging between 300 K/s and 1 K/s by in-situ XRD measurements.

The sample was levitated by the ADL system using a gas jet coming from a converging-diverging nozzle and heated by 2 CO2 lasers up to melting. The atmosphere was pure Ar gas or a mixture of Ar and O2 gas to generate reducing or oxidizing atmosphere respectively. The in-situ XRD measurements enabled observations of which crystalline phases formed as well as the dependence of the phase formation on the reducing or oxidizing atmosphere employed, different cooling rates, and the different mixture of CaO–SiO2 investigated.

These experiments were conducted at the Swedish Materials Science beamline, P21.1 branch.

Article

K. Schraut, F. Kargl, C. Adam, O. Ivashko, In situ synchrotron XRD measurements during solidification of a melt in the CaO–SiO2 system using an aerodynamic levitation system, J. Phys.: Condens. Matter. 33 (2021) 264003. doi.org/10.1088/1361-648X/abf7e1